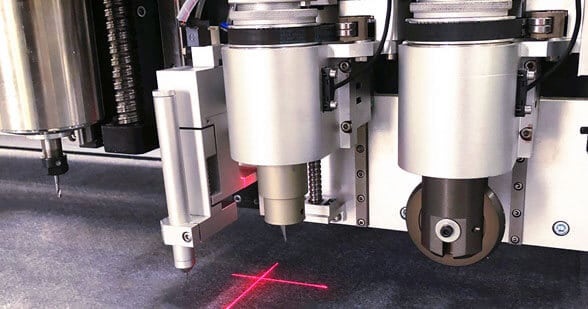

Composite materials are used in different industries, such as aerospace, automotive, marine, and construction, due to their excellent properties, such as high potency, durability, and corrosion resistance. However, cutting and machining composite materials can be difficult, as they are often hard and abrasive, and require precise and exact cutting to achieve the selected shape and size. firmuz.com offers top-of-the-line Composite Material Cutting Machines that are suitable for the various materials.

Increased Productivity

A composite material cutting machine is created to cut and machine composite materials quickly and efficiently, lowering the time and labor required for manual cutting. With a cutting speed of up to 60 inches per minute, a cutting machine can increase your productivity by up to 50%, allowing you to build more parts in less time.

Additionally, the accuracy of the Composite Material cutting machine ensures that each cut is accurate and uniform, resulting in high-quality finished developments. The machine is also equipped with protection features to protect the operator and control accidents. Whether you are working with carbon fiber, fiberglass, or other composite materials, a cutting machine can help you simplify your production process and enhance your bottom line.

Improved Quality

A high-quality composite material cutting machine can provide a class of precision and accurateness that is challenging to achieve with manual cutting. With a cutting accuracy of up to +/- 0.005 inches, a cutting machine can deliver that each part is cut to the exact size and shape, reducing the risk of errors and defects.

Reduced Waste

Cutting composite materials manually can result in a significant amount of waste, as the cutting process can be imprecise and lead to errors and faults. This can result in the need to discard parts that do not satisfy the required specifications, expanding the material and labor costs.

Lower Costs

Investing in a high-quality composite material cutting machine can help you lower your costs in several forms. Firstly, a cutting machine can lower the labor costs associated with manual cutting, as it requires less time and less experienced labor. This can free up your force to focus on more difficult and value-added tasks, such as design, engineering, and rate control.

Conclusion

Investing in a high-quality composite material cutting machine can bring significant advantages to your business, such as increased productivity, enhanced quality, reduced waste, and lower costs. Whether you are a small business or a considerable corporation, a cutting machine can help you remain competitive in today’s market by supplying a faster, more efficient, and more accurate cutting process.