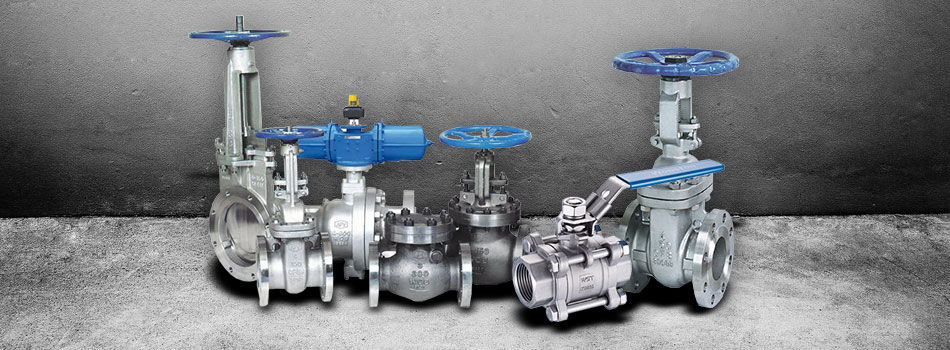

Valves in a hydraulic or air system are mechanical devices that regulate the flow and pressure of the fluid. They play a crucial role in piping systems that carry various substances, including liquids, gases, vapours, sludge, and more. Valves may be found in a wide variety, and each has its qualities, capabilities, and applications. Manual, pneumatic, electrical, etc., modes of control are all at your disposal for valves online.

Which Valve Should You Choose, And Why?

Knowing the intended use of the valve before making a purchase is essential. Does it control the flow of a fluid, or does it halt it? The next step is determining whether the system will use a gas or a liquid as its circulating medium. Does the medium need sterile conditions because it is corrosive, chemically neutral, a food product, or a medicinal fluid? Knowing whether the valve is powered manually or automatically when it comes to the operating system is crucial. For one, a person must be physically present to operate the valve, whereas, for the other, the valve may be managed from afar via a control centre. Last but not least, it’s crucial to understand the valve’s assembly and installation, including whether or not it will be welded, bolted via flanges, or screwed into place. After establishing these factors, you may shift your attention to the technical aspects of your installation, such as the flow and pressure, which will inform the sizing of your valve.

Find Out What Size Your Valve Needs To Be Using This Simple Formula

Understanding the operational characteristics of a circuit is necessary for calculating the valve’s physical size. It is crucial to consider the pressure so that you do not undersize your valve, which might lead to leakage or rupture or oversize it, which could cause it to fail prematurely.

Besides the ambient temperature surrounding the valve body, you need to know the operating temperature, which is the temperature of the circulating medium. The materials used in the body’s construction, the closure system, and the sealing elements must withstand the high temperatures the valve will be subjected to choose a suitable valve for use in these circumstances.

The medium pressure is circulated via the valve, also known as the operational pressure. The rate and speed at which the fluid is moving. The valve’s intended function, in this case, the control of a specific flow rate, necessitates consideration of both the desired flow rate and the nominal speed of the valve’s moving parts. Kv, or the flow factor, is a theoretical figure specified by the manufacturer to determine the valve’s nominal flow rate. Both litres per minute and cubic meters per hour (l/min and m3/h) are acceptable units of measurement. Many makers of valves provide tables that help you calculate this value from your desired flow rate and nominal diameter.

The DN value of the circuit that contains the valve. It is crucial to ensure the valve is neither oversized, which might cause installation instability, or undersized, resulting in a considerable pressure drop and quick valve breakage.

Conclusion

Valves with more than one intake or exit are known as multi-channel valves. Three-way valves, usually made of balls, are the most often used. These valves online are often placed between two separate circuits to control fluid flow inside the system. They also have the added benefit of combining two different liquids. Four-way, five-way and six-way valves are also available. Significantly few valves have more than this number of channels.