Introduction

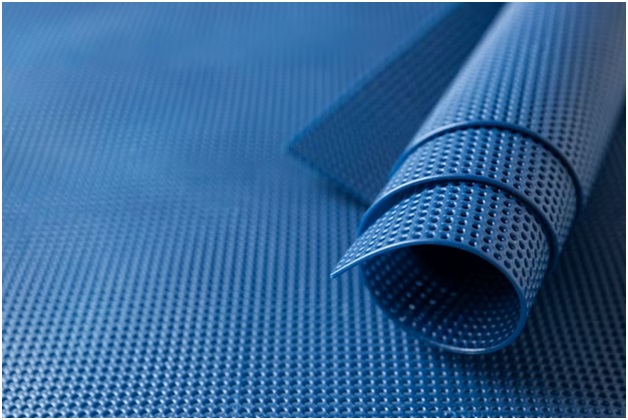

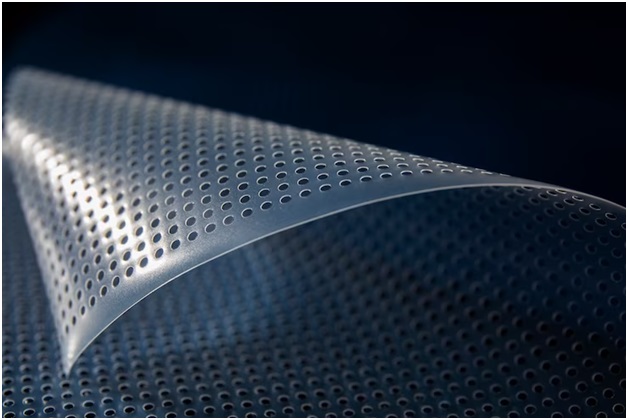

Glass fiber mesh, a versatile and multifaceted material, finds extensive application in a wide array of fields. Its usage spans from construction reinforcement to insulation and even as an appealing covering. Over the past few decades, this material has gained increasing popularity due to its numerous benefits, including being lightweight, durable, and cost-effective. The flexibility of glass fiber mesh allows it to be molded into various shapes, making it suitable for intricate designs or irregularly shaped spaces. Furthermore, it exhibits resistance to corrosion and degradation, setting it apart from alternative materials. In this article, we will delve into the diverse applications of glass fiber mesh and explore its advantages when compared to traditional materials.

Applications of glass fiber mesh

Glass fiber mesh has emerged as a popular choice for contemporary construction projects. Its design, characterized by lightweight, strength, and flexibility, renders it suitable for a plethora of applications, ranging from insulation to reinforcing concrete structures. Let’s take a closer look at the manifold uses of fiber mesh glass in construction projects.

Concrete reinforcement stands as one of the primary applications of glass fiber mesh. Acting as a supportive element, the mesh provides added strength to concrete, mitigating issues like cracking or structural damage resulting from temperature fluctuations, wind, or vibrations. This property makes it particularly suitable for outdoor areas like driveways and patios, where regular maintenance might prove challenging or expensive.

Moreover, glass fiber mesh serves as an excellent insulator against heat loss and noise pollution when installed within walls during construction. It effectively retains heated air inside buildings during colder weather while reducing noise levels originating from external sources such as traffic or nearby industrial machinery. In exterior wall applications, a thin layer of glass fiber mesh can be applied between two layers of brickwork, effectively repelling moisture while allowing for adequate air circulation, preventing the development of dampness over time.

Additionally, glass fiber meshes are increasingly popular among homeowners seeking effective fire protection measures for their residences.

Advantages of glass fiber mesh

Glass fiber mesh represents a remarkable material utilized across a wide range of applications, from construction to medical uses. Its advantages over traditional materials like steel, aluminum, and plastic have contributed to its growing popularity. In this section, we will explore the various advantages offered by glass fiber mesh, aiding in determining its suitability for your specific project.

One of the primary advantages of utilizing glass fiber mesh in construction materials lies in its exceptional strength. This material surpasses other options such as metal or plastic, making it suitable for structural reinforcement and seismic retrofitting projects where durability and strength are crucial. Furthermore, owing to its lightweight nature, glass fiber mesh reduces stress on supporting structures while maintaining high resistance against impacts and vibrations.

Compared to alternative materials, glass fiber mesh presents another notable advantage in the form of affordability. Glass fibers are relatively inexpensive when compared to metals like steel or aluminum, making them an attractive option for budget-conscious builders seeking quality products at a lower price point. Furthermore, glass fiber meshes require minimal maintenance, further contributing to long-term cost savings. Additionally, their durability and resistance to corrosion negate the need for regular upkeep or repairs typically associated with other building materials.

Lastly, glass fibers offer a multitude of creative possibilities due to their flexibility and adaptability. This attribute enables innovative and intricate designs that would be challenging to achieve with other materials.

Disadvantages of glass fiber mesh

While glass fiber mesh possesses several favorable qualities for construction and home improvement projects, it is essential to consider its disadvantages before making a purchasing decision.

One notable drawback of glass fiber mesh lies in its relatively high cost. The initial investment in the product, which depends on the desired quality and type, can often exceed the cost of materials like steel or concrete. Particularly when covering large surfaces or working within a budget, this cost factor can add up swiftly.

Another disadvantage stems from the comparative strength of glass fiber mesh. It does not match the strength of materials like steel or reinforced concrete, limiting its suitability for certain applications where robust support is a critical consideration. Additionally, due to the brittle nature of glass fibers, inadequate installation or maintenance may lead to cracks over time, resulting in costly repairs or replacements.

Installation can also present challenges due to the weight of glass fiber mesh. Handling becomes more demanding in comparison to lighter materials like wood or plastic sheeting. Furthermore, specialized tools and techniques are necessary to ensure proper adhesion between the mesh and the substrate surface, as failure to do so may compromise its effectiveness.

Different types of glass fiber mesh available

Glass fiber mesh, a versatile material used in construction and artistic endeavors, is available in several distinct types. Each type possesses unique characteristics and advantages, making it essential to understand the differences to select the most suitable option for your project.

E-glass Fiber Mesh: The most prevalent type in today’s market, E-glass fiber mesh exhibits excellent electrical insulation qualities and chemical resistance. It proves ideal for industrial environments where chemicals may be present, as well as residential applications where fire resistance is a crucial consideration. E-glass fiber mesh also provides good mechanical strength and corrosion resistance, making it suitable for various projects.

S-glass Fiber Mesh: S-glass fiber mesh shares similar properties with E-glass but surpasses it in terms of thermal stability and tensile strength. These characteristics make S-glass fiber mesh perfect for applications in high-temperature or corrosive environments, such as welding or automotive production lines. Moreover, S-glass fibers offer superior vibration dampening properties compared to traditional metal meshes, resulting in longer-lasting products with fewer defects caused by vibrations during operation or transportation.

Ceramic Coated Glass Fiber Mesh: Ceramic coated glass fiber mesh combines the advantages of glass fiber with a ceramic coating. This type provides enhanced resistance to heat and chemical exposure, making it suitable for demanding applications where extreme temperatures or corrosive environments are present.

Processes used to apply glass fiber mesh

Glass fiber mesh, with its strength, lightweight nature, and resistance to corrosion and fire, finds application in various fields. The application process depends on the specific requirements and desired outcome of the project.

The wet layup process represents the most common method for applying glass fiber mesh. It involves laying the mesh in a resin-based solution like epoxy or polyester resin, followed by curing with heat or ultraviolet light. The resulting product exhibits excellent adhesion properties, making it ideal for construction projects such as drywall reinforcement, roofing membranes, and swimming pool liners.

Another approach is the dry layup process, where an adhesive backing is applied to the back of the mesh before placing it onto the desired surface. The adhesive ensures firm adhesion upon curing with heat or ultraviolet light, making it suitable for applications requiring strength and durability, such as wall paneling or floor tiles.

Additional methods include vacuum bagging, which entails sealing airtight bags around pre-cut pieces of glass fibers before heating them under pressure, as well as lamination using pressure-activated adhesives, pultrusion, and filament winding.

Factors influencing the application process

The application process plays a pivotal role in the success of a job search, potentially determining whether one secures the desired role or faces disappointment. Several factors come into play, influencing the application process from start to finish. Understanding and addressing these factors can significantly enhance one’s chances of success.

Preparation stands as a critical factor when it comes to applications. Thorough research is essential, not only about the job role and company but also their competitors and the industry as a whole. This background work allows for the effective tailoring of resumes or CVs, enabling candidates to demonstrate alignment with specific positions and better prepare for interview questions.

Presentation represents another vital aspect that should not be underestimated. Resumes or CVs need to be clear, concise, and tailored to each position applied for, as recruiters expect a personalized approach from every candidate. Generic templates raise red flags and suggest a lack of effort. Moreover, documents should be free from typos and spelling mistakes, as such errors indicate carelessness that may cost potential opportunities.

Networking can also exert a significant influence on the success of applications. Building connections within the industry and utilizing professional networks can provide valuable insights, recommendations, and opportunities that might not be available through traditional application channels.

In conclusion, glass fiber mesh finds broad applications across various industries, offering strength, durability, and versatility. Its uses span construction, insulation, filtration, and more. The material’s flexibility allows it to adapt to a range of shapes and sizes, making it suitable for diverse projects. Additionally, glass fiber mesh presents a cost-effective alternative compared to other construction materials, making it an appealing choice when cost considerations are paramount. With its blend of strength, durability, and affordability, glass fiber mesh emerges as an ideal solution for projects requiring robustness and longevity at an affordable price point.